When you’re working with screws, it’s helpful to know the different parts of a screw and their purposes.

Screws may be confused. Follow Oukailuo and learn what each part does to get a good understanding of how screws work.

This article will introduce the common parts of the screw and detail each part for you to have a better understanding.

Key Parts of a Screw

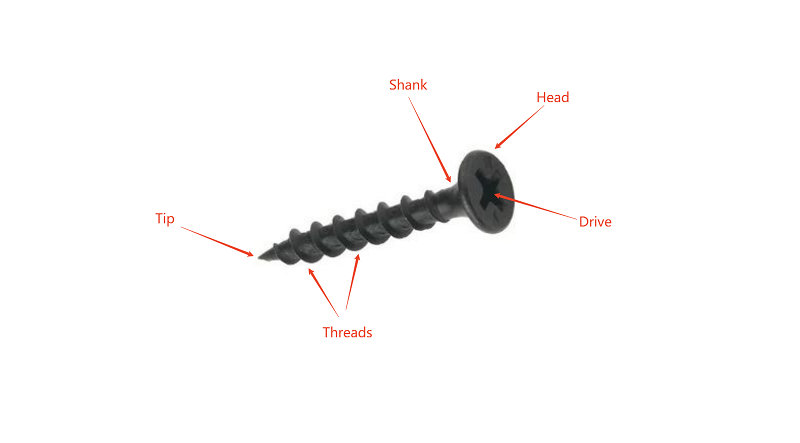

The head is the top section of the screw, typically wider than the rest of the body, and serves as the interface through which the screw is driven into materials.

Additionally, the drive system located in the head which determines the type of tool required to engage and turn the screw. This system not only facilitates ease of installation and removal but also helps prevent slippage and damage to both the screw and the driving tool.

Beneath the head lies the shank, the smooth, cylindrical portion that extends down the length of the screw. The shank provides structural strength and stability, ensuring that the screw can withstand the forces applied during fastening without bending or breaking.

Surrounding the shank are the threads, which are helical ridges that spiral around the screw’s body. These threads are crucial for gripping and pulling materials together as the screw is turned, allowing for secure and tight connections.

The tip of the screw, also known as the point, is engineered to penetrate the material with minimal resistance, often featuring a sharp or tapered design to initiate insertion smoothly.

Screw Head Types

The head of the screw is what you see first. There are many head types, but there are two main types: countersunk and non-countersunk.

Countersunk screw heads have a tapered design that allows the head to sit flush with or below the surface of the material they are driven into. Common styles of countersunk heads include flat, oval, and bugle heads.

In contrast, non-countersunk screw heads do not taper, resulting in the head being fully exposed above the material’s surface. Typical non-countersunk head types include binding, button, cheese, fillister, flange, hex, pan, round, socket, square, and truss heads.

Shank and Threads

From the head to the tip, there is the shank and threads. This part the core of the screw, providing the foundation for the threads. There are two parts to the shank:

- Unthreaded Shank (unthreaded portion): Also known as the smooth shank, this portion is typically located near the head of the screw. Unlike the threaded section, the unthreaded shank lacks the spiraling grooves that characterize the rest of the screw.

- Alignment and Centering: The smooth shank helps to center the screw within the pre-drilled hole, ensuring that the threads engage the material evenly and reducing the risk of cross-threading.

- Load Distribution: By providing a smooth surface, the unthreaded shank helps distribute the load more evenly along the length of the screw, which can prevent material splitting and enhance the overall stability of the connection.

- Insertion Depth Control: In applications where precise insertion depth is required, the smooth shank acts as a buffer between the head and the threaded portion, allowing for controlled fastening without overdriving the screw.

- Threaded Shank (Grooved Section): Extending from the smooth shank, the threaded section features spiraling grooves known as threads.

- Enhanced Grip: The threads provide the necessary grip to secure the screw firmly within the material. As the screw is driven in, the threads cut into the material, creating a tight and reliable fastening that resists loosening over time.

- Self-Tapping Capability: In many screws, the design of the threads allows for self-tapping, meaning the screw can create its own path as it penetrates the material. This feature eliminates the need for pre-drilling holes in softer materials and speeds up the assembly process.

- Load Bearing: The threaded shank is responsible for bearing the load applied to the screw. The depth and pitch of the threads determine how much weight the screw can support, making them a key factor in selecting the appropriate screw for a given application.

- Resistance to Vibration: In environments subject to vibration or movement, the threads help maintain the screw’s position by increasing the friction between the screw and the material. This resistance prevents the screw from loosening, ensuring the longevity and reliability of the fastening.

Screw Tip Varieties

The tip is the part that goes into the material first. Tips can vary depending on the screw’s purpose. The two common types are:

- Sharp Point: The sharp point is one of the most prevalent screw tip designs. Characterized by a finely tapered and pointed end, this tip allows the screw to penetrate materials with minimal initial force.

- Self-drilling: Self-drilling screws feature a tip that resembles a drill bit, complete with fluted or spiral grooves that mimic the cutting edges of a drill. This design enables the screw to create its own hole as it is driven into harder materials like metal, eliminating the need for a pre-drilled pilot hole.

Different Screw Thread Style

Screws come in a variety of designs, each with unique thread patterns and driving mechanisms that suit different material types and applications.

1. Unified Thread Standard (UTS)

The Unified Thread Standard (UTS) is a prevalent thread system used primarily in the United States and Canada. It encompasses both Unified National Coarse (UNC) and Unified National Fine (UNF) threads.

- Unified National Coarse (UNC): Characterized by larger thread pitches and deeper threads, UNC screws are designed for general-purpose applications where quick assembly and strong holding power are required.

- Unified National Fine (UNF): Featuring finer threads with smaller pitches, UNF screws offer greater surface contact and enhanced strength.

2. Metric Thread

The Metric Thread system is widely adopted internationally, particularly in Europe and Asia. It is standardized under the ISO 68-1:1998 specification and is identified by its thread pitch in millimeters.

- Metric Coarse (M): Similar to UNC, metric coarse threads have larger pitches and are used for general fastening purposes.

- Metric Fine (MF): Analogous to UNF, metric fine threads have smaller pitches, allowing for higher precision and stronger clamping forces.

- Metric Extra Fine (MEF): An extension of the fine thread category, metric extra fine threads offer even smaller pitches for specialized applications that demand extremely high precision and strength.

3. British Standard Whitworth (BSW)

The British Standard Whitworth (BSW) thread is an older thread system primarily used in the United Kingdom and former British colonies. It is characterized by a 55-degree thread angle and larger thread pitches compared to modern standards.

- BSW Coarse: Employed in heavy-duty applications such as construction, shipbuilding, and railway systems.

- BSW Fine: Offering smaller pitches than their coarse counterparts, BSW fine threads are used in applications requiring tighter tolerances and greater strength.

Materials and Coatings

Common Material Options

Most screws are made from steel, because it’s strong and durable. However, if you need something resistant to rust, stainless steel screws are your best bet. They’re ideal for outdoor projects or environments with a lot of moisture. You’ll also find screws made from other materials like brass and aluminum, but these are less common.

Coating Types for Protection

A screw’s coating is like a shield. It stops rust and other damage, which makes the screw last longer. Here are a few types of coatings:

- Zinc: This is a popular choice for a finish because it provides a good level of protection at a reasonable cost.

- Ceramic: These coatings can stand up to more wear and tear than many others.

- Copper: While not as common, copper coatings can be useful in certain situations for added corrosion resistance.

Other coatings include bronze, ceramic, and blackphosphate.

Different Type of Screws From Oukailuo

Oukailuo Wood Screws

Black Oxide Carbon Steel Truss Head Wood Screws

Featuring a wide, flat head that distributes pressure evenly, these screws prevent material splitting and ensure a secure attachment. Perfect for decking, cabinetry, and furniture assembly, their robust construction provides durability and longevity.

- High-Strength Construction: Made from durable materials for long-lasting performance in demanding applications.

- Sharp Threads: Facilitates easy penetration into the wood, reducing installation time and effort.

- Corrosion Resistant Coating: Provides added protection against rust and environmental damage.

- Compatible Drive Types: Fits standard flathead and Phillips screwdrivers for versatile use.

Oukailuo Machine Screw

Yellow Zinc Plated Phillips Machine Screw

These machine screws are coated with vibrant yellow zinc plating, offering excellent resistance against rust and environmental damage.

The Phillips drive provides a secure fit, ensuring efficient installation and removal. Perfect for metal assemblies, machinery, and industrial applications, these screws deliver dependable performance and longevity.

- High-Strength Material: Manufactured from durable steel for reliable performance in heavy-duty applications.

- Precision Threads: Designed for consistent threading and optimal grip in metal and machinery components.

- Versatile Usage: Suitable for various industrial applications, including machinery, equipment assembly, and metalwork.

- Variety of Sizes: Available in multiple lengths and diameters to meet diverse project needs.

- Easy Installation: Compatible with standard tools for efficient and hassle-free fastening.

Are you ready to achieve unparalleled quality and reliability in your fastening solutions? Discover Oukailuo’s extensive range of high-performance screws and fasteners designed to meet the diverse needs of industries worldwide. Need high-quality fasteners? Contact us.