Concrete anchors are essential for securing objects to concrete surfaces.

Understanding the different types of concrete anchors helps you choose the right one for your project, ensuring safety and durability.

There are various concrete anchor types, each designed for specific weight capacities and installation methods.

Mechanical anchors, like wedge anchors and sleeve anchors, expand to grip the concrete tightly. These are great for heavy-duty tasks and are easy to install.

Whether you’re working on a home renovation or a large commercial project, knowing the right concrete anchor to use can make all the difference.

By choosing the correct anchors, you can ensure your fixtures stay secure and your worksite remains safe.

Definition of Concrete Anchors

Concrete anchors are specialized fasteners used to attach objects to concrete surfaces, playing a crucial role in construction, renovation, and various industrial applications.

When using concrete anchors, it is essential to drill a hole that matches the anchor size to effectively fasten to concrete and ensure a strong hold in the base material.

These anchors provide a reliable means of attaching fixtures, structural components, and equipment to concrete, which is a common building material known for its strength and durability.

The use of concrete anchors is essential in ensuring the stability and safety of installations ranging from household items to large infrastructure projects like bridges and buildings.

Types of Concrete Anchors

Concrete anchors come in various types, each suited for specific applications.

Common types of concrete anchors include wedge, sleeve, drop-in, machine screw, and lag shield anchors.

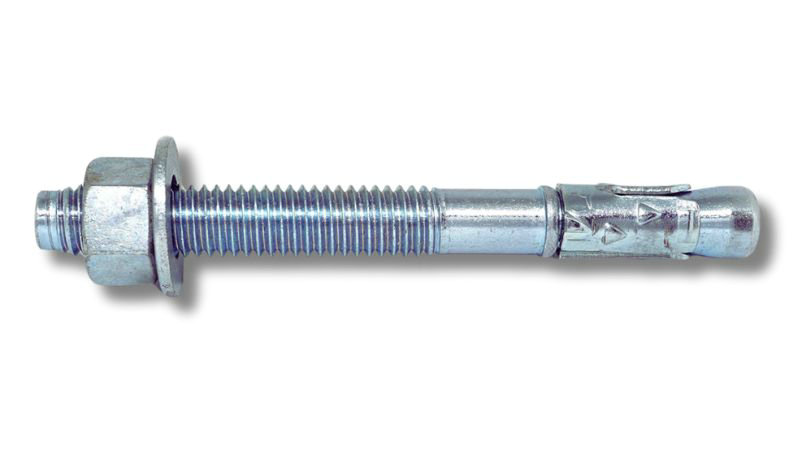

Wedge Anchors

Concrete wedge anchors, one of the strongest concrete anchors, are male anchors.

They are commonly used for heavy-duty applications, such as securing large machinery or structural elements.

The heavy-duty anchors expand when tightened, providing a secure hold.

They come in multiple diameters and lengths, offering options based on your load requirements.

Wedge anchors can also resist corrosion, making them ideal for both indoor and outdoor use.

Ensure you choose the right size and material for the best performance.

Sleeve Anchors

Sleeve anchors are versatile and easy to install.

They are used in both solid and hollow concrete, as well as brick and block. This makes them ideal for a range of applications, from mounting shelves to securing light fixtures.

The anchor comes in various sizes, suited for light to medium loads.

Drop-In Anchors

Drop-in anchors are designed for concrete ceilings and floors.

They are installed flush with the concrete surface and provide a solid anchor point for threaded rods or bolts.

These anchors can’t be used effectively in brick, block, mortar, or stone.

They come in different sizes to match the diameter of the threaded rod or bolt you plan to use.

Machine Screw Anchors

A machine screw is a female anchor used to secure objects to concrete.

These anchors have internal threads that accept the screw.

The concrete screw is suitable for light to medium loads and provides a strong hold.

It requires a pre-drilled hole, into which the anchor is inserted. Tightening the machine screw expands the anchor, securing it in place.

This type of anchor is often used for mounting electrical boxes or small fixtures.

Lag Shield Anchors

Lag shield anchors are used with lag bolts.

They come in various diameters and lengths, allowing you to choose the best size for your needs.

Lag shield anchors are ideal for medium to heavy-duty applications, such as anchoring outdoor structures or heavy equipment.

Their ability to handle large loads makes them a reliable choice for many projects.

Selection and Installation

Concrete anchors are essential in providing stability and safety for various projects.

To make the right choice and ensure proper installation, consider factors like load requirements, material compatibility, and the correct installation techniques.

Determining Load Requirements

Knowing the load requirements is crucial for selecting the appropriate anchor.

Different projects require different types of loads: dynamic (moving loads) or static (stationary loads).

Understanding the weight and force the anchor will need to support helps avoid failure. Some common load types include:

- Light Loads: For items like pictures or lightweight shelving.

- Medium Loads: For heavier shelving or TV mounts.

- Heavy Loads: For structural elements or heavy machinery.

Use load calculations along with safety margins to select an anchor that can handle the anticipated stresses.

Choosing the Right Anchor for Material

The material you are anchoring into also influences your choice.

For solid concrete, use wedge anchors or sleeve anchors.

Brick and block might require lag shield anchors.

Each material has different properties that impact anchor effectiveness:

- Concrete: Offers high holding strength for most anchors.

- Brick and Block: May require anchors that expand to grip the uneven surfaces.

- Drywall: Needs anchors that spread the load to prevent tearing.

Be cautious with mixed materials like stone or mortar, choosing anchors that accommodate their unique textures and strengths.

Installation Method and Tips

Proper installation starts with drilling the right size hole.

Use a hammer drill for solid materials like concrete or stone. Here are key steps:

- Mark the drilling location.

- Drill a pre-drilled hole in the concrete: Match the drill bit size to the anchor requirements.

- Clean the hole thoroughly with a vacuum to remove debris.

- Insert the anchor: Insert it into the walls of the hole, and ensure it is straight and snug.

- Tighten the anchor: Use a wrench or screwdriver, depending on the type.

Always follow manufacturer’s instructions to ensure a secure fit.

For mortar or block, avoid drilling into edges to prevent weakening. Regularly check anchor stability over time, especially in dynamic load situations.

Maintenance and Performance

To ensure the longevity and effectiveness of concrete anchors, it is essential to focus on proper maintenance and performance checks.

Key elements include corrosion resistance, using the right materials, and conducting regular inspections.

Corrosion Resistance and Material Choices

Concrete anchors are exposed to varying environmental conditions.

Corrosion resistance is a crucial factor to consider.

Anchors made from materials like stainless steel offer excellent resistance to rust and corrosion, making them ideal for outdoor or moisture-prone areas.

Carbon steel anchors, while strong, are prone to rust if not properly coated. Galvanized or zinc-coated options can enhance their durability.

Choosing the right material will depend on the specific environment and load requirements.

Regular Check-ups for Anchors

Maintaining concrete anchors involves regular inspections. You should check them at least once a year, or more often in harsh environments.

Look for signs of rust, corrosion, or loosening.

Pay special attention to areas exposed to moisture or chemicals. If you notice any wear, it might be necessary to replace the anchors.

Tighten any loose anchors to ensure they continue to perform well.

Keeping a maintenance log can help track the condition of your anchors. Documenting each inspection and noting any issues can ensure timely repairs and replacements.

By consistently following these practices, you can extend the lifespan of your concrete fasteners and maintain the safety and stability of your structures.