When it comes to installing plasterboard, choosing the appropriate screws is vital for achieving a sturdy and long-lasting result. The right screws ensure that the plasterboard is securely fastened to the underlying structure, such as studs or framing.

Factors like screw length, thread type, head type, and coating play significant roles in determining the performance and durability of the installation. This article explores the key considerations when selecting screws for plasterboard, helping you make informed choices for your next project.

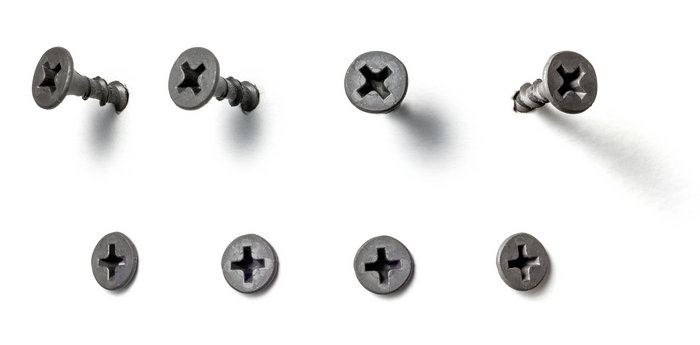

Drywall Screw Features and Terminology

Head shape of a drywall screw – Drywall screws feature a bulge head; a variation of a countersunk screw. This design is particularly suitable for softer materials, allowing the screw to sit flush with the finished plasterboard surface.

Thread type of drywall screws – The coarse threads make them well-suited for screwing into wood, providing rapid insertion and creating a solid and secure fastening for the plasterboards.

The fine thread has a narrower gap between each thread. Fine thread screws are more difficult to drive, but they also create a smaller hole in the drywall.

Screw point – Drywall screws feature a sharp point facilitating quick pick-up into the timber. The sharp point allows for efficient and easy starting of the screw into the material.

Material and coating of drywall screws – Drywall screws are typically made of hardened, brittle steel and come with a phosphate coating. They’re primarily designed for use with softwood and may be prone to snapping when used with harder materials. The phosphate coating is a protective layer, guarding against corrosion and safeguarding the screws from moisture in the timber.

Drive type of drywall screws – Drywall screws employ a Philips drive type. Using a Philips drive reduces the risk of the screws pulling through the plasterboard. However, it’s essential to note that Philips drive screws may tend to cam out when encountering resistance, meaning they may slip or disengage from the screwdriver tip.

Coarse Thread vs. Fine Thread Drywall Screws

Coarse thread drywall screws have more comprehensive, deeper threads spaced farther apart. These screws are designed to provide a firmer grip and are commonly used for attaching drywall to wood framing.

The coarse thread screws bite into the wood more aggressively, providing better holding power. They’re ideal for use in thicker drywall panels or requiring additional strength and support.

On the other hand, fine-thread drywall screws have narrower, closer-spaced threads. They’re typically used for attaching drywall to metal studs or other metal framing materials.

The fine threads have a shallower bite, allowing easier insertion into metal without causing damage. Fine thread screws are preferred for thinner drywall panels, as they reduce the risk of cracking or splitting.

Self-Drill Drywall Screws

Self-drilling drywall screws are specially designed fasteners used in construction for attaching drywall panels to metal or wooden studs without pre-drilling pilot holes. They feature a sharp, pointed tip and fine threads that allow them to penetrate and secure drywall directly into the framing material.

The self-drilling feature eliminates the need for separate drilling and saves time during installation. These screws typically have a bugle head design, which helps to countersink the screw slightly below the surface of the drywall, facilitating the finishing process. Self-drilling drywall screws are efficient, convenient, and widely used in residential and commercial construction projects.

Selecting the Right Size Plasterboard Screw

Drywall Screw Lengths

To select the correct drywall screw length, consider the thickness of the drywall and the depth of the material being attached. The screw length should be slightly longer than the combined thickness of the drywall and any underlying material, ensuring a secure and flush installation.

Drywall Screw Gauges

Consider the thickness of the drywall and the type of framing material when selecting the correct drywall screw gauge. #6 screws are commonly used for 1/2-inch drywall, while #8 screws are suitable for 5/8-inch drywall. Thicker or denser materials may require higher gauge screws for adequate strength.

Uses of Drywall Screws

Drywall Screw Uses in Construction

Drywall screws have numerous uses in construction. They’re primarily used for attaching drywall panels to wooden or metal studs. They provide a secure and stable connection, ensuring the stability and integrity of interior walls and ceilings.

Drywall screws are also used to install corner beads, secure trim or molding, and mount fixtures or accessories onto drywall surfaces. When installing drywall, it’s crucial to drive the screws in straight instead for clarity. to ensure a seamless and professional finish.

Can You Use Drywall Screws for Building?

While drywall screws are primarily designed for attaching drywall to studs, they’re not typically recommended for general building purposes. Drywall screws may lack the strength and durability required for structural applications.

How Many Drywall Screws per Pound?

Estimating the number of drywall screws required for a plasterboard project can be challenging as they’re typically sold by weight rather than quantity. However, there are some estimates available to help you plan.

For instance, if you have a pound of screws, you can expect approximately 200 coarse thread #6 screws that are 1-5/8 inches long.

Similarly, for 1-1/4-inch coarse thread #6 screws, you can estimate around 238 screws per pound.

If you opt for 2-1/2-inch coarse thread #8 screws, the approximate count would be 92 screws per pound.

While these estimates can give you a rough idea, purchasing a bit more than required is always recommended to account for any unforeseen circumstances or errors during installation.

Choosing the Right Type of Drywall Screw for Your Project

Choosing the right type of drywall screw for your project is essential for ensuring a successful and durable installation.

Factors to Consider

Firstly, determine the purpose of the screws and ensure they are suitable for your specific project, such as attaching drywall to metal studs or wood framing. Consider the screw’s characteristics, including head type (bugle head for minimal damage), point (sharp for easy starting), and compatible drill bit (usually a #2 Phillips).

Coatings are also crucial, with options like phosphate for corrosion resistance or vinyl for improved driving. Selecting the right size and thread type for your specific application is equally important.

How to Drive Drywall Screws

Start at the corner or edge: Begin at one corner or edge of the drywall sheet. Position the screw on the surface, aligned with the stud or framing member behind.

Apply gentle but firm pressure to the screw, keeping it perpendicular to the drywall surface.

Drive the screw: Using a drill or screwdriver, drive the screw into the drywall. Maintain a steady and controlled speed to avoid damaging the drywall or stripping the screw.

Sink the screw: Continue driving the screw until it is flush with the surface of the drywall. Be careful not to over-tighten, as it may cause the drywall to crack or dimple.

Repeat the process: Move along the drywall sheet, positioning screws at regular intervals, typically 12 to 16 inches apart, along the studs or framing members.

Check for flushness: As you drive each screw, periodically check that it is flush with the drywall surface. Adjust as needed to ensure a smooth finish.

Tips for Avoiding Common Mistakes

To avoid common mistakes when using drywall screws, follow these tips:

- Avoid overdriving or underdriving the screws to maintain the integrity of the drywall.

- Ensure proper spacing between screws, typically 12 to 16 inches apart.

- Choose the correct length and type of screws for your project.

- Use caution to prevent damaging the drywall while driving the screws.

Adhering to these guidelines can achieve a secure and professional installation while minimizing potential issues.

Conclusion

There are many different types of screws available for use with plasterboard. The type of screw that is best for a particular project will depend on the thickness of the plasterboard, the weight that the plasterboard will need to support, and the type of framing member to which the plasterboard will be attached. Choosing suitable screws for the job and using them correctly ensures a secure and long-lasting installation.