Selecting the correct screw size is crucial to ensure the success and integrity of your project. Using the wrong size screw can lead to material damage or a weak and insecure connection. For this important reason, this article will walk you through the process of measuring screw size, equipping you with the knowledge to make informed choices on the best screw size for your needs.

Importance of Measuring Screw Size

Here’s why measuring screw size is important:

- Measuring the screw length will help you know if it matches the thickness of the material being worked on. A short screw cannot securely hold the object, while an overly long one can cause damage or protrude from the material, posing safety risks.

- It helps you drill the correct diameter for the hole. The thread diameter measurement helps you to confirm that it matches the size of the hole. A screw that is too small won’t fit properly, leading to a weak connection, while a large one can cause the material to split or crack.

- Appropriate thread pitch for the material: Pitch measurement helps ensure proper compatibility with the material. Coarse-threaded screws provide stronger holding power but may be more likely to damage the material. Fine-threaded screws offer finer adjustments and are suitable for more delicate materials.

- By accurately measuring screw size, you can select screws that match your project requirements, ensuring a secure and reliable connection without damaging the materials involved.

Types of Screw Measurements

- Screw Length

A screw’s length is measured from the base of the head to the tip except for countersunk head screws, where the length should be measured into the head. This measurement is typically given in millimeters or inches.

- Diameter

The screw’s diameter is measured across the threads. This measurement is typically given in millimeters or inches.

Major Diameter vs. Minor Diameter vs. Pitch Diameter vs. Nominal Diameter

It’s essential to know the three different types of diameters when working with screws:

- Major Diameter: This is the outside diameter of the threads.

- Minor Diameter: This is the inside diameter of the threads.

- Pitch Diameter: This is the diameter of an imaginary cylinder that passes through the center of the threads.

- Thread Pitch: The thread pitch of a screw is the distance between the peaks of two adjacent threads. This measurement is typically given in threads per inch (TPI) or threads per millimeter (TPM).

- Threads Per Inch (TPI)

Threads per inch (TPI) is a measurement of the number of threads that are on a screw in one inch. The higher the TPI, the closer together the threads are.

- Screw Weight

Screw weight varies depending on the type of screw, its material, and its size. For example, a small wood screw made of steel will weigh less than a large lag screw made of stainless steel.

How to Measure Screws

Screw Length

The most distinct screw measurement is its length, which is determined by measuring the distance from the flat part of the head to the tip or blunt end of the screw. However, the variety of screw head types adds complexity to this measurement.

Here’s an overview of different screw head types and how to measure screw length for each:

- Screws with a flat bottom head (non-countersunk): Measure from the flat bottom of the head to the tip or blunt end of the screw.

- Flat head screws (countersunk screw): Measure from the flat top of the head to the tip or blunt end of the screw.

- Screws with oval heads: For oval head screws, measure from the widest point of the head to the tip or blunt end of the screw.

Diameter

Understanding these four diameters is essential. Here’s how each is measured:

- Major diameter: The largest diameter of a screw’s thread, measured from the crest (top) of one side to the crest of the other side.

- Minor diameter: The smallest diameter of a screw’s thread, measured from the root (bottom) of one side to the root of the other side.

- Pitch diameter: The diameter of a theoretical cylinder that lies halfway between the major and minor diameters. It is typically used for rolling threads on new parts.

- Nominal diameter: An estimated major diameter used as a shorthand term. It simplifies reference to one of the important diameters. For example, a rounded nominal diameter is often used instead of the precise major diameter measurement.

Thread Pitch

Thread pitch refers to the distance from a point on one thread to the corresponding point on the next. It can be measured from the crest, trough, or any point.

For metric parts, measure thread pitch in millimeters. Remember that larger pitches indicate coarser threads, while smaller pitches indicate finer threads. Consider screw strength and ease of installation when selecting thread pitch.

Threads Per Inch (TPI)

The thread pitch is measured in threads per inch (TPI) for inch parts. Count the number of threads within a 1-inch length of the screw. A lower TPI indicates coarser threads, while a higher TPI indicates finer threads. Similar to the metric system, this information is important for considering screw strength and ease of installation.

Standard inch thread pitch measurements fall under the Unified Screw Thread System grouping. The two most common groupings are:

Unified National Coarse (UNC): Coarser pitches with deeper threads.

Unified National Fine (UNF): Less thread depth and larger tensile stress area.

Screw Weight

Because of slight variations in structure, manufacturing processes, and even chemical composition among most fasteners, relying on the weight of a single screw to represent the entire batch can be inaccurate.

Instead, a more dependable approach is to weigh multiple screws and calculate an average based on these measurements. This method accounts for any inconsistencies and provides a more reliable representation of the overall weight of the batch.

Measuring Small Screws and Metric Screws

Using a Screw Gauge for Small Screws

Measuring small screws accurately using a ruler or measuring tape can be challenging. However, a handy tool called a screw gauge can help measure the diameter and thread pitch of small screws.

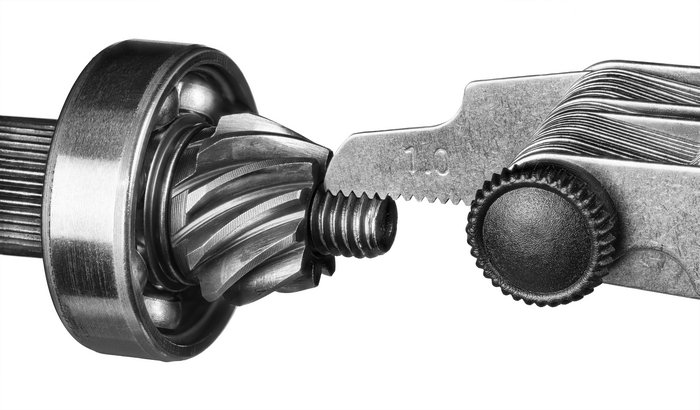

To utilize a screw gauge, simply position the screw between the jaws of the gauge and tighten it until it is securely in place against the stops. The scale on the gauge will indicate the diameter of the screw.

To measure the thread pitch, rotate the screw until one complete turn is achieved. The scale will then display the number of threads that have passed the stops, allowing you to determine the thread pitch accurately.

Understanding Metric Screw Measurements

Metric screws are identified by their diameter and length measurements, both specified in millimeters. For example, an M6-10 screw has a diameter of 6 millimeters and a length of 10 millimeters.

The thread pitch of a metric screw indicates the distance between the peaks of two adjacent threads and is measured in millimeters per turn. For instance, an M6-10 x 1.0 screw has a thread pitch of 1.0 millimeters per turn.

Gears and Pitch

How Gears Relate to Screw Measurements

Gears and screws are mechanical devices that utilize rotational motion to transfer power. Gears transmit power between rotating shafts, while screws fasten objects. The pitch of a screw and gear is the distance between threads or teeth. A higher pitch means greater power transmission capacity.

Importance of Pitch in Gears and Screws

The power transmission capacity of a screw or gear depends on its pitch. A higher pitch enables a screw or gear to transmit more power than a lower-pitch counterpart.

Pitch also plays a role in determining the rotational speed of a screw or gear. A higher pitch results in a faster rotation speed, while a lower pitch corresponds to a slower rotation. Engineers and designers find the relationship between gear and screw measurements significant when selecting suitable application components.

Choosing the Right Screw Size for Your Application

Factors to Consider

- Load capacity: The ability of a screw to support weight is determined by factors such as its diameter, length, and material. Using the correct size of screw for the task at hand is crucial. The wrong size of a screw can damage the fastened material and result in the screw loosening.

- Material type: Screws are manufactured from various materials, including steel, stainless steel, and brass. Select a screw made from a material that’s compatible with the fastened material.

- Environmental factors: The environmental conditions of a screw impact its resistance to corrosion and lifespan. In harsh environments such as saltwater or extreme temperatures, it’s advisable to use screws made from corrosion-resistant materials.

Screw Selection Process

Assessing the Application

To choose the right screw, start by understanding the application. Consider the load capacity, material type, and environmental conditions. The load capacity is how much weight a screw can handle. It depends on the screw’s diameter, length, and material. The material of the screw affects its strength, durability, and cost. They can be made of steel, stainless steel, or brass. Also, consider the environment where the screw will be used.

Choosing the Right Screw Material

The material of the screw is important for its strength and durability. Pick a material suitable for your application. For high-load situations, use a strong material like steel. In corrosive environments, choose corrosion-resistant materials like stainless steel.

Determining the Required Screw Size

Consider the screw’s diameter, length, and material to ensure it meets the requirements of your application.

Conclusion

Understanding how to measure screw size is essential for choosing the right screw for your project. By considering factors such as diameter, length, and pitch, you can accurately determine the appropriate screw size.

Additionally, taking into account load capacity, material type, and environmental conditions ensures optimal performance and longevity of the selected screw. With this knowledge, you can confidently select the perfect screw size to achieve successful and reliable results in your applications.