The subfloor is a critical structural component of any flooring system. It provides stability and support for the finished flooring material above. To properly install a subfloor that will withstand the test of time, it is important to choose the right type of fastener. This article will explore the best screw options for securing subflooring and provide recommendations on which screws are most suitable for different subflooring materials and job conditions.

Brief Introduction to Subfloor

Your subfloor is a critical component of your home’s foundation, providing a flat, stable surface on which your decorative flooring will be laid. No matter you are building your own house or just renovating the room, you will definitely encounter it

The subfloor is typically made from plywood or OSB (Oriented Strand Board) and is attached to the floor joists, which are horizontal structural members that support the floor loads.

When choosing a subfloor material,plywood subfloors are popular due to their sturdiness and durability. It’s essential to select a thickness suitable to span the distances between thejoists.

Here’s a quick list of considerations for your subfloor installation:

- Material Choice: Opt for plywood or OSB based on your preference and budget.

- Joist Inspection: Since the joist is the structural member of your floors. Ensure joists are level and free of damage before laying the subfloor.

- Installation Method: Securely fastening the subfloor to the joists with appropriate screws is a significant way to help you prevent future issues like squeaking.

Subfloor VS. Underlayment

Subfloor and underlayments serve distinct purposes in floor construction. Typically, a floor structure contains four key components:

The floor covering is the topmost visible layer that makes up the walking surface. Directly below is the underlayment, which functions to absorb vapor and protect the subfloor from damage from the floor covering material above it.

The subfloor forms the next layer and provides a rigid surface and platform for floor installation. It is secured directly to the structural joists. These joists span the underside of the floor and support both the subfloor and the entire floor assembly.

Choosing the Right Screw For Subloors

When tackling a subfloor project, the screws you choose are pivotal to the quality and longevity of your floor. It’s about selecting the right type of screw, size, and features that match your specific subfloor needs. People sometimes choose nails as their first choice, but nails do not always offer a tight connection.

This section will provide you with what screws to choose when you install the subfloor.

Screw Types

Several types of screws are suitable for subfloors, each designed to address different aspects of construction.

The three main categories of subfloor screws include: galvanized screws, cement board screws, and steel screws.

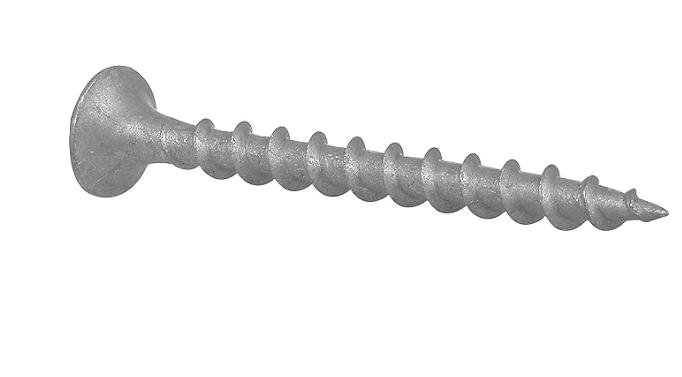

- Galvanized screw: Galvanized screw is named after a manufacturing process. It refers to a screw made of steel or iron that has been coated with a layer of zinc to prevent rusting and corrosion. The zinc coating is typically quite thick in hot-dip galvanizing, over 45 μm. This makes galvanized screws much more corrosion resistant compared to zinc plated screws which have a thinner layer of zinc applied by electroplating rather than dipping. Galvanized screws are suitable for exterior use and exposure to harsh conditions. The zinc coating will eventually corrode in non-salty environments but can last for many decades.

- Cement board screw: Cement board screws have a corrosion-resistant coating to withstand moisture and alkalinity without rusting (Common coatings include zinc, ceramic, or a multilayer coating. It has sharp points and wide threading. Standard lengths are 1-1/4″, and 1-5/8″ for metal studs. Longer screws are available.

- Steel screw: Steel screws are commonly made from carbon steel or alloy steel. Grades 2, 5, and 8 carbon steel screws are typical for fastener applications. They offer good strength and durability.

Steel screws can be plain/unfinished, or have coatings like zinc plating, galvanizing, or chroming applied. These help protect against corrosion, especially for outdoor use. Stainless steel screws contain chromium (at least 10.5%) which gives excellent corrosion resistance. Common grades are 304 and 316 stainless. Steel screws are available with different head shapes (flat, pan, oval) and drive types (Phillips, Torx, hex). They come in a wide range of thread types, diameters, and lengths.

Deck screws and drywall screws can also be used in subfloor installation, however, they are not highly recommended.

Drywall screws are not hard enough for the subfloor and are easy to snap off.

Desk screw size is about 2 1/2 to 3 inches which is too long for the subfloor. Generally, for a 5/8″ OSB subfloor, 1 1/2″ screws are sufficient. For 3/4″ plywood subfloors, 2″ screws are better to account for the extra thickness. Moreover, desk screws often cost higher in projects.

A few critical features define a high-quality subfloor screw:

- Coating: Look for a durable coating that prevents corrosion, such aszinc or galvanized finishes.

- Head Type:Flathead screws lie flush with the material, providing a smooth finish.

- Thread and Tip: Screws with sharp tips and aggressive threads are easier to install and provide better holding power.

Size and Length

The right size and length of screws can ensure your decoration of the floor is fastened and suitable; here is the recommendation to you.

- Size: Heavier and larger subfloor panels require thicker, heavy-duty screws. Common range from #8 to #10, or #12 which indicates the thickness and diameter.

- Length: The shortest screws used in subfloor installation is 11/14 inches, and the longest is 3 inches. To find out which length is suitable for you, you should know how thick your floor is. Your screws should penetrate at least 1″ into the floor joist. For example, if your plywood is 3/4″ thick, a 1 3/4″ screw is appropriate.

Preventing and Fixing Squeaks

Squeak Causes

Understanding why your floors squeak is essential to prevention and repair.Squeaks primarily occur due to movement between subfloor components, typically at the seams where they meet. As you walk across the floor, the plywood or particleboard used in the subfloor can rub against the floor joists, nails, or screws, causing a squeaking sound. This is often due to the nails loosening over time, leading to gaps and movement.

To prevent squeaking, choose the correct materials of the subfloor and screws and use the right installation methods.

So in summary, installing inappropriate screws or nails for the subfloor can lead to frustrating squeaky floors sooner than expected after finishing the work.

Squeak Solutions

If you’re already faced with squeaky floors, here are steps to fix it:

- Identify the Squeak:

- Walk over the floor to pinpoint the exact location of the squeak.

- Choose the Correct Screws:

- Opt for subfloor screws that are specifically designed to reduce squeaks, such as those with a flat head and partial threading for extra grip.

- Installation:

- Secure the subfloor to the joists with screws. Tightening them draws the subfloor closer to the joists and reduces movement, which is often the cause of squeaking.

- Replacing nails with screws can be effective, as screws tend to hold the subfloor tighter against the joists over time.

Following these steps can help you minimize or eliminate squeaks in your flooring, leading to a more peaceful and quiet home environment.

Subfloor Installation Techniques

In subfloor installation, precision is paramount. By knowing where and how to place your screws, and understanding the nuances of driving them in, you’ll set the stage for a sturdy, squeak-free floor.

Proper Spacing and Placement

For optimal support, distribute screws evenly across the subfloor. When working with plywood or Oriented Strand Board, follow these guidelines:

- Begin by laying your sheets perpendicular to the floor joists.

- Spacing: To avoid your subfloor buckling, you should place screws 8 inches apart along the joists and 6 inches around the sheet edges.

- Edge Support: Ensure the long edges of the plywood align with the center of the joists.

Pre-drilling and Driving Tips

Pre-drilling and driving your screws correctly preserves the integrity of your flooring. To maximize torque and minimize effort, consider these tips:

- Pre-Drilling: Use a drill bit slightly smaller than the diameter of your screw.

- Driving Screws: Drive screws flush with the subfloor to prevent any raised screw heads that could affect your finish flooring.

For heavy-duty projects, use a powerful drill that can handle the extra torque needed to drive screws without stripping the heads. Always use a screw bit that fits snugly in the screw head to reduce cam-out.

Additional Considerations for Subfloor Screws

When selecting the right screws for your subfloor, it’s not just about size and strength. You need to consider environmental factors and material compatibility to ensure the longevity and proper performance of home decor.

Environmental Factors

Exterior Floors: If you’re working with outdoor or exposed subflooring, you must use screws that are rust-resistant. Materials often subjected to the elements, like pressure-treated lumber, should be paired with screws designed to cope with corrosive chemicals and moisture.

- Moisture Exposure: Choose stainless steel or galvanized screws to prevent rust and corrosion.

- Chemical Treatments: Make sure the screws are compatible with chemically treated lumber to avoid metal degradation.

Material Compatibility

Interior Subfloors: When dealing with interior floors, your focus can be on structural integrity rather than weather resistance. Screws designed for plywood or OSB should be used accordingly to ensure a secure fit without damaging your materials.

- Plywood: Use screws that grab well and resist shearing. Wider threads can provide a better grip.

- OSB: Avoid screws that are too large, as OSB can split easily. Choose ones with finer threads.

Cement Board Screws: In cases where you’re installing cement board as a subfloor, especially in moist areas like bathrooms, ensure you’re using specially designed cement board screws that can anchor securely without risking damage to the material.

Ensure you check the compatibility of screws with your specific subfloor material—this will aid in achieving a solid and lasting installation.

In summary, the type of screw used for installing subflooring depends on the material being fastened and the expected loads and stresses. For lightweight subfloors like plywood or OSB, small screws provide a secure fastening that won’t loosen over time. Heavier-duty construction screws are recommended for attaching solid wood subfloors or subfloors in high-traffic areas. Galvanized options provide corrosion resistance. With the right screw fastener anchored at the proper spacing, homeowners can have confidence in a subfloor that will ensure a sturdy, durable finished floor for years to come.